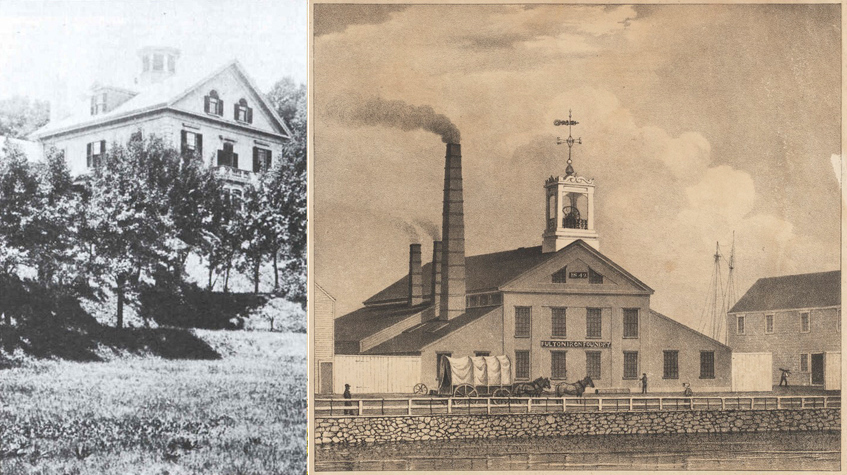

Dorchester Illustration 2566 Thacher House and Fulton Iron Foundry

The Thacher family estate is at the left of today’s illustration. It was known as “Hillside,” and was located on the north side of Jones Hill. The building at the right is the Fulton Iron Foundry.

George C. Thacher was a founder and owner of the Fulton Iron Foundry, which was located in South Boston, at the intersection of Dorchester Avenue and Foundry Street, with offices on Long Wharf, in Boston. The location provided easy access to the then navigable Fort Point Channel, as well as connections to railroad lines, with spurs connecting directly to foundry buildings. Thacher’s foundry was not the only one in South Boston in the mid-19th century. By 1850, Cyrus Alger’s South Boston Iron Works, a corner of which can be seen at the lower right on this map, was the largest foundry in the country. There is no doubt, however, that Thacher’s Fulton Iron Foundry was profitable. Founded in 1835, it began in a period where railroad lines were being laid out rapidly and, although there was competition from cheaper English iron, iron rails and locomotives would have been a major source of business. In addition, of course, iron was in demand for everything from nails to stoves. By the mid19th century, iron foundries dominated the “lower end” of South Boston. The lithograph, from the collection at the Boston Public Library, shows the Fulton Iron Foundry in the period 1842-1856. The legend says: “The Fulton Iron Foundry. Geo. C. Thacher, Thomas Thacher and Thomas. T.Thacher, Jr., Proprietors.” [This paragraph was taken mostly from a house history report written by Marti Glynn in the Dorchester Historical Society’s house history project. You can see finished reports on the Society’s website. www.dorchesterhistoricalsociety.org.]

The foundry sat on about seventy-five thousand feet of land with a foundry building of sixteen thousand feet on one level equipped with large cranes and containing four melting furnaces, five ovens for drying, large molds for dry-sand and loam-work. Store-houses for sand, coal and a large stock of patter, an engine-house , buildings for dressing castings, making patterns and flasks, and blacksmith work, stable, and other structures are grouped near the foundry. Among the specialties manufactured are machine castings, such as large steam cylinders, propellers and channel plates for marine engines; gearing, pulleys, kettles for the refinery of oil, sugar and resin; appliances for chemical works, columns for buildings and generally heavy castings. Source: J. D. Van Slyck. New England Manufacturers and Manufactories. Volume 2 (Boston, 1879), 752-753.